Palletize mixed size cases On the Fly

capabilities:

Optional Configurations

Technical

Palletize Mixed Size Cases On the Fly

A Random Case Palletizer is an advanced automation solution designed to streamline the process of stacking cases of various sizes and shapes onto pallets in a random order without the need for manual pre-sorting or sequencing. It uses sophisticated software and vision systems to identify and position cases, optimizing pallet layouts for stability and space efficiency. This technology adapts in real-time to changing inventory, handling diverse products precisely. By doing so, it significantly reduces labor costs, increases throughput, and minimizes the physical strain on workers, making it an indispensable tool in modern warehousing and distribution centers.

On the fly palletizing

Instantly adapting to mixed box sizes and orientations, enabling seamless, uninterrupted packing and stacking in real-time.

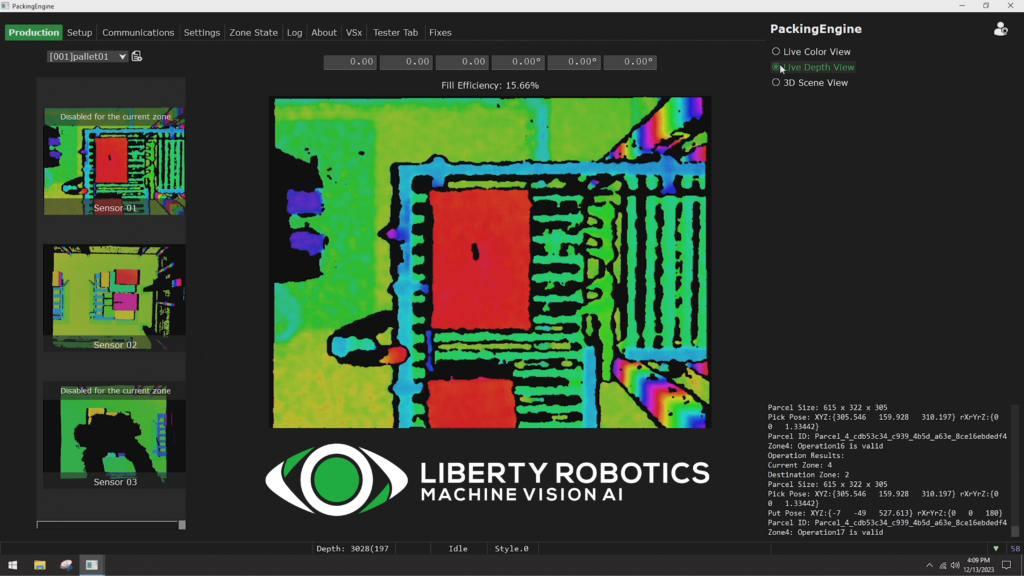

3D Vision System

Enabling precise, real-time object recognition and positioning for efficient automation processes.

Multiple Build Locations

Simultaneously constructs pallet stacks at multiple locations, optimizing throughput and workspace utilization with mixed case capabilities.

Setup a Live Demo with your products

Contact us to discuss your mixed build and we can arrange a demonstration using your products at our John D. Schuster Innovation Center in Toledo, Ohio.

A Case of Automation

Developed with a keen focus on the end user, this system has undergone rigorous testing to ensure unmatched flexibility in its operation. Acknowledging the diverse demands of the modern workplace, it has been engineered to adapt seamlessly to a wide array of operational environments, product types, and workflow requirements. Throughout its development, the primary goal has been to create a solution that not only meets but exceeds the expectations of end users. By prioritizing versatility and user-friendliness, the system stands as a testament to a development process that places the end user’s needs at the forefront, ensuring that it can effortlessly integrate into, and enhance, any production line.

How it Works

Truly on the Fly

No specific stacking pattern is required for boxes, eliminating the need for pre-determined arrangements.No Sequencing Required

Supports both sequenced and spontaneous (“Ad Hoc”) picking and packing, catering to varied operational needs.Lights Out Automation

Designed for optimal performance in both lit and unlit environments, ensuring round-the-clock operations.No Layer Count Issues

Operates without needing the count of boxes per pallet layer, adding to its intuitive design.3D World Model

Capable of handling multiple layers without disruption, even if an extra box is added unexpectedly.Variation of Products

Accommodates a wide range of box sizes, ensuring versatility across different products and packaging standards.Playing Tetris

Requires no system training with minimal SKU-specific parameters, emphasizing ease of use and fast integration.Case Reading

The type of printing on the boxes is irrelevant to system operation, further simplifying the process.No Robot Retraining

No need to retrain robots if case sizes change, printed materials change, or End-of-Arm Tool Changes.Pick Speed

No need to retrain robots if case sizes change, printed materials change, or End-of-Arm Tool Changes.Liberty Robotics 3D Vision

Liberty Robotics and Autotec Solutions are at the forefront of the Random Case Palletizing evolution, pushing the boundaries of the field with their joint focus on research and development. Their efforts aim to not only improve current capabilities but to fundamentally transform industry standards, introducing solutions that are smarter, more adaptable, and significantly more efficient. This collaboration is redefining expectations by closely aligning with market needs, paving the way for the future of automated palletizing systems. A key component of their innovative approach is the Precision Robotic Guidance, powered by the VPack™ machine vision system. VPack significantly enhances robotic packaging efficiency by accurately assessing boxes on conveyors to determine their ideal placement on pallets. This system guides robots to precisely pick and place boxes, preventing collisions and optimizing pallet layouts. With its high-resolution sensors, VPack guarantees exceptional detection and handling of boxes by scrutinizing their dimensions and orientation, ensuring impeccable execution in complex manufacturing and packaging scenarios.

Compact Footprint

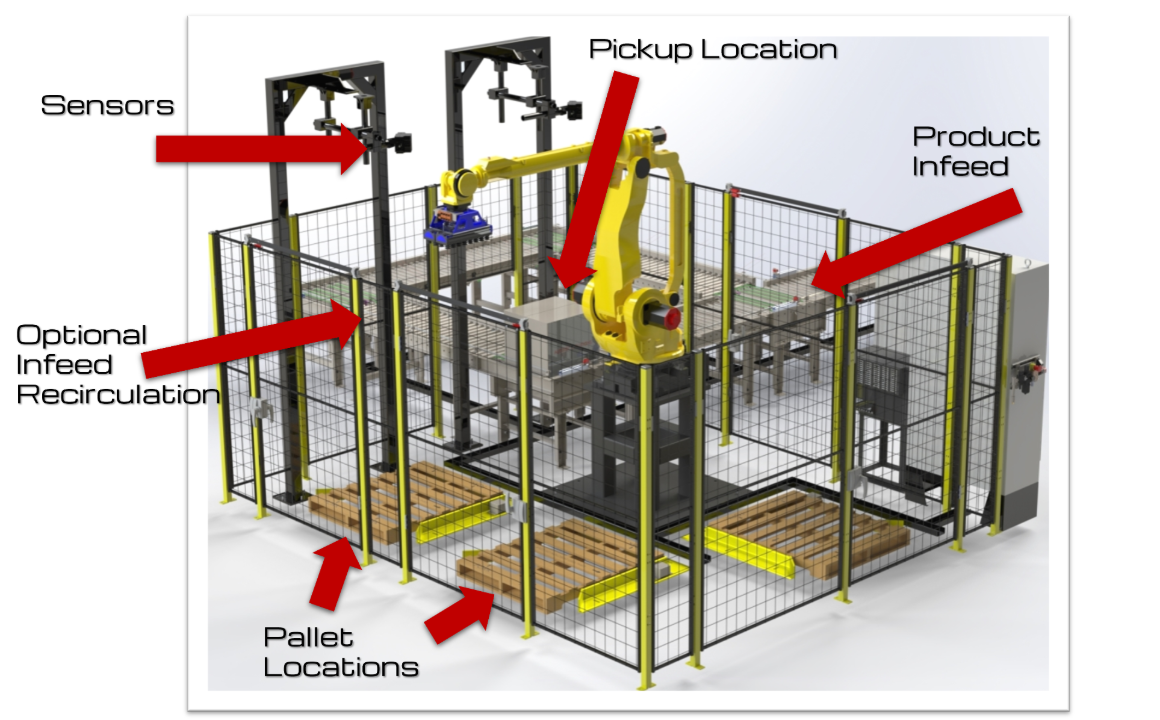

The system boasts a compact footprint, starting at 300 sq feet within the fence and expanding to 600 sq feet with an optional infeed conveyor, maximizing space efficiency. Its versatile vision system is primarily mounted above pick and build areas but can attach to the robot’s EoAT for more complex configurations, offering flexibility in adapting to varied operational demands.

Forward Looking Partnership

Liberty Robotics and Autotec Solutions are leading the evolution of Random Case Palletizing. Their collaborative commitment to research and development is driving innovative advancements in this technology field. The aim is not only to enhance current capabilities but also to revolutionize industry standards with smarter, more flexible, and highly efficient solutions. They are setting new benchmarks by understanding and responding to market needs, transforming automated palletizing systems for the future.

On The Fly System Integrations

Numerous integration options exist for incorporating the random case palletizer into various warehousing and manufacturing systems. We’ve established several standard system integrations, including rotary arm stretch wrappers, conveyors that interface with Autonomous Mobile Robots (AMR), and robots mounted on rails.

Rotary Arm Stretch Wrapper

The Rotary Arm Stretch Wrapper is an automated system with an infeed, wrapper zone, and outfeed conveyor. It wraps stationary loads with a 20-inch film, featuring a 200% standard pre-stretch for 60 to 100 gauge films. Safety is ensured with fencing and a light curtain, capable of wrapping loads up to 87 inches high. The machine offers adjustable wrap patterns through the HMI and includes a pop-up feature for thorough wrapping.

Interfaces for Mobile Robots

Our AMR (Autonomous Mobile Robot) Interfaces expertly streamline automated material handling, facilitating more effective warehouse workflows. Autotec provides solutions like top module conveyors and AMR-compatible pallet jack ramps for the autonomous movement of materials. Modular and adaptable, these designs merge seamlessly with current operations, maximizing space utilization and boosting efficiency without the need for manual input.

Robots On Rails

The optional Robotic Transfer Unit elevates productivity to new levels. This state-of-the-art addition, functioning as a robot on rails, incorporates robot-mounted vision technology. It effectively increases the number of pick and build locations, thereby enhancing overall operational efficiency. By capitalizing on this feature, businesses can significantly maximize their spatial utilization and throughput, making it a worthy investment for high-volume operations.